Table of Contents

Introduction to 3D printing in medicine

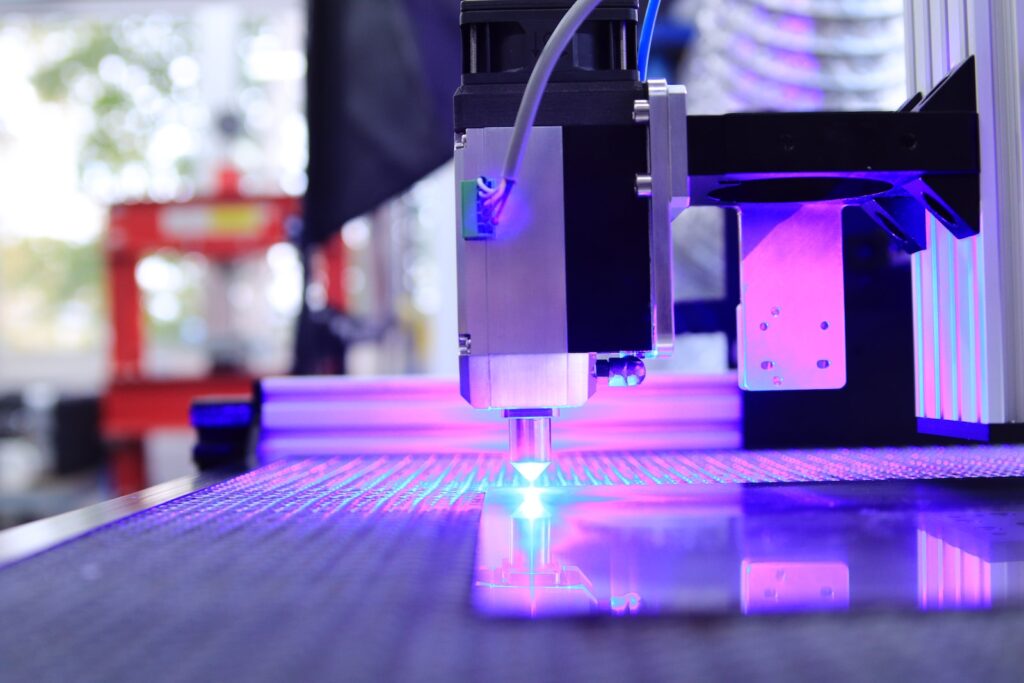

The use of technology within the medical industry has revolutionized healthcare, making treatments and procedures faster, more efficient, and less invasive. One of the most significant technological advancements in recent years is the utilization of 3D printing.

A process previously used to create models for architecture and engineering uses digital designs to manufacture three-dimensional objects by layering materials such as plastic or metal until they form a complete product. This technique has since been adapted for medical purposes where it is used to produce prostheses or implants that are tailored specifically for individual patients.

Until now, devices like hearing aids have been manufactured using computer-aided design (CAD) software which creates digital images from patient scans; these images are then converted into Gcode- machine code language instructing on how much material needs depositing at each point – this data is then sent to the printer which constructs an exact replica of the scanned area. The applications extend well beyond creating dental impressions or custom hearing aids with a number of potential uses including surgical planning tools, bioprinted skin grafts for wound repair and bone scaffolds designed specifically with an intricate internal structure that allows cells to grow through them.

As printing technologies continue improving alongside advances made in imaging techniques like magnetic resonance imaging (MRI) or computed tomography (CT), we find ourselves closer than ever before towards providing personalized treatment options based on unique anatomy. The ability to print devices specific shapes also means that physicians can create bespoke equipment not commercially available helping increase efficiency further reducing costs.

Applications of 3D printing in healthcare

The use of 3D printing technology has revolutionized the medical field and has shown to have a significant impact on improving patient care. Some of the applications of this technology include:

1. Patient-specific models for surgery planning: Surgeons can now create accurate replicas of the affected body part to visualize complex surgeries beforehand, which reduces time spent in the operating room and increases precision during surgery.

2. Prosthetics and implants: With 3D printing technology, creating customized prosthetics or implants is made possible at a fraction of previous costs. This is especially helpful when treating children who require growing prostheses as they age.

3. Educational tools for medical training: Medical students can learn anatomy using realistic models created with high precision and accuracy through 3D printers.

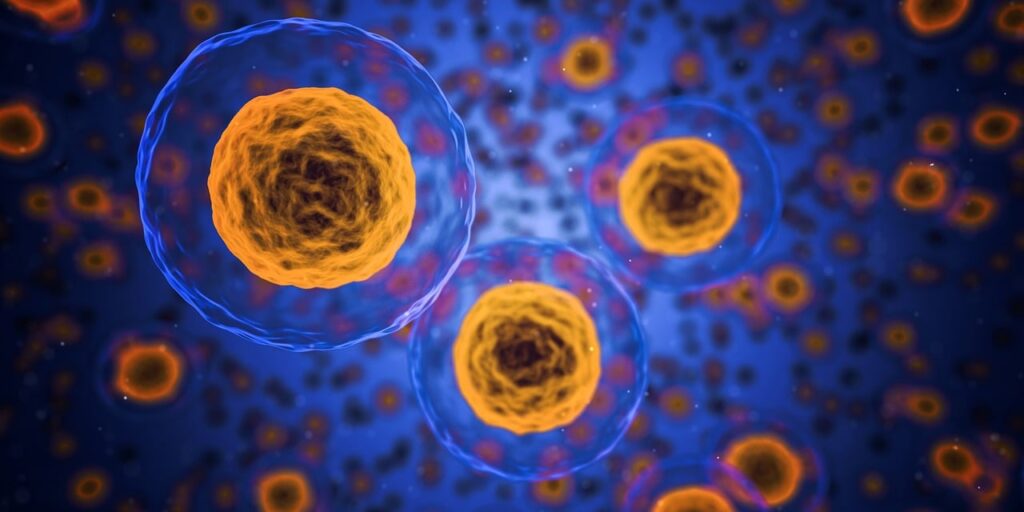

4. Skin grafts & cartilage replacements: In recent years, there have been remarkable developments surrounding skin grafts & cartilage replacements through bio-printing; researchers have used living cells rather than plastic or metal materials- forming tissues that will grow within patients’ bodies naturally over time!

The benefits offered by this innovative technology go beyond those listed above – providing unique treatment opportunities including improved outcomes, efficiency throughout processes involved from analysis up until aftercare; such that more personalized approaches are made possible thanks to both increased diagnostic certainty alongside expanded areas within which individualization becomes viable!

Advantages and Challenges of 3D printing technology in healthcare

3D printing has various advantages and challenges in the healthcare sector. On one hand, it offers a lot of benefits such as customized production for personalized treatments, faster delivery times, reduced costs, and improved patient outcomes.

The first advantage is that 3D printing enables medical professionals to produce very precise models from scans or data sets. This precision can be especially important when creating implants or prosthetics tailored specifically to an individual’s anatomy.

In addition to accuracy, 3D printers allow for quicker turnaround time than traditional manufacturing methods. Products can be created almost instantly with the help of computer-aided design (CAD) software and then printed using layers upon layers of materials like metal powders or plastics.

Another great benefit is that this technology reduces overall expenses on both large-scale products like surgical instruments or machinery and smaller items such as hearing aids or dental crowns. The ability to print parts on demand means there’s no need for excess inventory, which in turn lowers business risk by minimizing waste and overheads.

This technology also makes it possible for doctors to develop detailed simulations before performing procedures like surgeries. Medical professionals are able to better visualize complex structures within a patient’s anatomy beforehand resulting in less invasive surgery techniques being developed over time..

Challenges:

With any new technology comes some potential downsides too – particularly when it involves risk factors associated with human health issues; however we have seen tremendous advancements made throughout these last few years addressing many of these challenges around safety concerns while strategically reducing risks through ongoing evaluations.

One challenge has been how best physicians use & validate information gathered – there are still limitations related towards industry standardization efforts due not only differing regulation policies but scalability across multiple platforms making interoperability between systems challenging at times .

Critical Research:

Another important challenge is the need for continued research into 3D printing’s impact on patient safety and outcomes over time. With the rapid adoption of new technology, it’s essential that professionals working in healthcare take steps to ensure that patients receive the best possible care.

In conclusion, although still in its early stages, 3D printing technology has already made an incredible impact on the healthcare industry. As this revolutionary manufacturing method continues to evolve we can anticipate significant advancements in medical engineering achieved through strategic collaborations and partnerships between manufacturers & healthcare providers alike

The role of 3D printed implants and prostheses on patient outcomes

One significant area where the use of 3D printing technology in healthcare has been revolutionary is in creating custom-made implants and prostheses. Before the advent of this technology, patients often had to rely on off-the-shelf products that were not always a perfect fit for their specific needs.

With advancements in medical imaging, doctors can now print exact replicas of bones or other body parts based on a patient’s CT scan or MRI. This means that surgeons can have an incredibly detailed and accurate model to work from during procedures and develop tailored treatments designed specifically for each individual.

In addition, another key advantage of using this type of additive manufacturing process is the ability to incorporate unique features into each implant or prosthesis. For example, it is possible to fabricate porous structures within these devices which stimulate bone growth by allowing natural tissue ingrowth around the implant structure. This ensures better fixation which reduces loosening over time compared with conventional metallic orthopaedic implants alone.

This flexibility also means that physicians are no longer limited by what is readily available since they can create components tailored precisely according to their preferences; thus making surgeries less invasive as there would be fewer risks associated with complications from ill-fitting components such as discomforts after surgery due to poor fitting substitutes.(Muller et al.,2018)..

Future prospects of 3D Printing Technology In Medicine

One area is personalized medicine. Imagine a future where prosthetics and implants are created specifically for each patient using their individual anatomical data. This would result in better fit and comfort for patients, ultimately improving their quality of life.

In addition, 3D printing can revolutionize surgical planning by allowing surgeons to practice complex procedures on models that mimic the exact anatomy of the patient before performing the actual surgery. This will reduce operative time and improve accuracy while minimizing complications arising from human error.

Besides surgical planning, 3D printed medical devices like custom-made dental crowns or hearing aids could become widely available at lower costs due to more efficient manufacturing processes associated with additive manufacturing techniques used by printers.

An additional benefit is related to education as medical students who use such models during training get exposed to real-life-like scenarios even before they ever lay hands-on human patients. It increases student confidence levels and helps them prepare better for real-life surgeries when dealing with complex cases that require mastery level proficiency levels

Looking forward into the realm of research — Scientists will be able to simulate new medications experimentations through simulations before administering them on test subjects thereby reducing drug testing timescales whilst keeping subjects safer during trials.

Lastly, bio-printing holds great promise in regenerative medicine where tissues or structures damaged due to disease or injury can uniquely designed using stem cells combined with other biological elements offering a solution towards successfully treating conditions previously thought untreatable.”

In conclusion,

The advancement being made via additive manufacturing technologies like ‘3D Printing’ holds the promise to make significant paradigm shifts in medicine. Approaches that were once considered unattainable have been made possible, and new possibilities for treatment have arisen. As more research is conducted and public awareness continues to increase, we can expect even more breakthroughs with potential life-changing effects of 3d printing technology in healthcare

Conclusion: The Impact Of Advanced Technological Innovation On Healthcare Through the Use Of ‘Additive Manufacturing.’

In conclusion, it is evident that additive manufacturing or 3D printing technology has had a significant impact on the healthcare industry. Although this innovative technology is still in its early stages of development, the potential benefits it offers to medical applications cannot be denied.

The use of patient-customized implants and prostheses have been shown to improve patient outcomes significantly. By creating tailored solutions to an individual’s unique needs and utilizing materials suited for their specific uses, doctors can provide faster surgeries with better results while reducing post-operative times spent recovering in hospitals.

However, despite all the challenges associated with implementation and production difficulties due to bio-materials’ unfavorable reactions at times during printing processes when not properly optimized, there are several advantages as well which make exploring these opportunities crucial for our society moving forward into an age where advanced innovation reigns supreme over traditional methods!

“Moreover,”

It holds great promise as one possible solution towards achieving higher standards & fostering improvements within Quality Control procedures alongside developing ever-changing regulations – leading us further down progressive paths other technologies may fail entirely without understanding how quickly things like “Industry4.0” could evolve them towards success by merging innovation+data insights made possible through IoT (Internet-Of-Things) integrated platforms created by adapting customized enterprise software solutions if implemented effectively today…

, so

it would be wise

[to] stay up-to-date

on these advancements if we want healthier lives ahead!